Automotive/Vehicle EMC & EMI Testing – Overview, Testing Standards, FAQ

Automotive EMC/EMI

Electromagnetic interference and compatibility in automotive or vehicle applications offer a unique set of challenges distinct features and challenges. EMI is defined by the International Organization for Standardization in ISO 7637-1:2015 Preview(accessed 8/20/19) as “any electromagnetic phenomenon which can degrade the performance of a device, equipment or system, or adversely affect living or inert matter … An electromagnetic disturbance may be an electromagnetic noise, an unwanted signal or a change in the propagation medium itself."

EMC testing is the process of determining the impact that the anticipated electric environment will have on equipment as well as ensuring that equipment doesn't interfere with devices in that same environment. This testing is broken down into two different components components immunity and emissions.

Testing criteria, methods, and levels will typically be unique to automotive requirements given the nature of vehicles and changing electrical environments. Test requirements for automotive applications also differ from other areas in the amount of both OEM and International standards that are commonly used for products.

Pre-compliance & Compliance Testing

Automotive tests can be done at both the pre-compliance and compliance levels. Pre-compliance is often done in typical lab settings where some or part of the testing levels, setup, or other considerations aren't followed. Opposite to this compliance testing is done following 100% of the requirements in the standard. Some tests lend themselves well to pre-compliance such as conducted tests, whereas others are more commonly compliance test lab settings.

Automotive Immunity Testing

Immunity testing is broken down into conducted and radiated tests, which are commonly required for automotive devices to be tested. Conducted immunity is focused on transmission of interferance or noise via direct contact. The automotive sector is unique in the amount of OEM standards, however to we are going to focus on the most common international requirements, ISO 7637-2/3, ISO 16750-2, ISO 11452-4, and ISO 10605.

Radiated immunity test subject equipment to varying levels of electric and magnetic fields in an effort to ensure no impact on the functioning of the device. The most common standards for this type of testing is ISO 11451-2 and ISO 11452-2.

Conducted Immunity

Conducted immunity testing done on applications designed for automotive or vehicle applications typically include:

- ESD Testing to ISO 10605

- Transient Tests to ISO 7637-2/-3

- Conducted RF Testing to ISO 11452-4

ESD Testing

ESD testing for automotive applications typically requires different equipment than is used for commercial testing. While some of the general design characteristics of the test simulators remain the same (discharge tip design etc.) many specific design requirements differ. This can be most commonly seen in the higher test levels reaching up to 25 kV or above as well as the different resistance and capacitance networks required for testing. The video on the right illustrates how ESD simulators used in testing function as well as how networks used in testing are switched out on the Teseq NSG 438.

Networks for ISO 10605 ESD testing as well as other automotive international standards and OEM requirements will include:

- 150 pF 330 Ohm Network

- 330 pF 330 Ohm Network

- 150 pF 2k Ohm Network

- 330 pF 2k Ohm Network

These different combinations are designed to replicate real world events where the inductance and capacitance will change. In automotive applications, this could be a person placing a key into a door or touching a conductor connected to the electrical system.

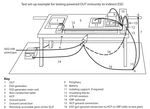

Testing in automotive or ungrounded applications also offers challenges when applying multiple pulses which is typical in ESD testing requirements. Unlike many other applications, there is typically not a path to ground facilitating the need to remove the charge to continue testing. As with other applications testing can be conducted both directly and indirectly to the device under test (DUT) as well as via air or contact discharge. The below illustrates an automotive setup used in indirect discharge testing.

Transient Testing

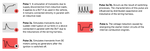

Transient testing is commonly done to ISO 7637-2/-3 which is covers transmission of transients via power or data lines. These two sections within the ISO 7637 series are the most commonly tested and referenced by associated OEM specific standards for automotive transients. Some automotive pulses, as with EFT/Microbursts, are similar to commercial requirements with some modifications to pulses to account for the automotive environment. Below are typical transient test requirements and a brief overview of the most common waveforms.

ISO 7637-2/-3

ISO 16750-2 - Load Dump Pulses

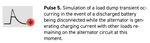

This standard provides a few different pulses including superimposed voltage and momentary dip testing, however it is most commonly referenced for it's load dump (5a) and clipped load dump (5b) waveforms. These pulses are typically test to in conjunction with the ISO 7632-2 pulses covering a wider range of automotive transients.

Radiated Immunity

Radiated immunity testing is commonly conducted for full vehicle testing to ISO 11451-2 and component level testing to ISO 11452-2 and ISO 11452-5. This testing will vary in testing level from 50 V/m up to 200 V/m (or beyond) and can be conducted at one meter or two meter distances. As with other radiated immunity tests a series of amplifiers, antennas, and other equipment is used to expose the device under test toa AM modulated signal using the substitution method.

There are a few notable difference between ISO 11451/2 radiated immunity testing and commercial radiated immunity requirements.

- Frequency Range - ISO 11451/2 can extend testing from 10 kHz to 18 GHz

- Power Requirements - To achieve test levels at lower frequency high power equipment is needed

- Modulation - ISO 11451-2 uses 50 V/m with 80% peak conservation

The below image illustrates the test concept of radiated immunity testing.

Conducted Emissions

Conducted emissions for automotive applications is typically conducted with a LISN and EMI receiver or spectrum analyzer for pre-compliance testing. The LISNs used in testing are typically 5uH which are designed to replicate the lower inductance of the power system of a vehicle. Some of the most common conducted emissions requirements and inductances used in testing can be seen in the image below.

CISPR 25

CISPR 25 is the most common automotive conducted emissions requirements which is commonly used in automotive testing. This standard includes requirements on the LISN design and setup as well as conducted emissions levels.

The associated video on the Teseq HV-AN 150 which provides testing capabilities to CISPR 25 as well as other 5uH requirements. It goes into detail about the LISNs including the shielded metal enclosure.