6 Types of EMC Test Equipment & Common Applications

EMC Test Equipment & Applications

EMC test equipment covers a wide range of testing applications and can overlap with more general electrical test equipment such as spectrum analyzers, signal generators, etc. However, the majority of equipment used will be designed for a particular test requirement ensuring that equipment under test (EUT) meets the associated requirements.

What is EMC Test Equipment?

Electromagnetic Compatibility (EMC) test equipment is designed to evaluate if electrical/electronic equipment will function in its anticipated electrical environment or cause unintended interference in that environment.

EMC testing is broken down into four main subcategories, conducted immunity, radiated immunity, conducted emissions, and radiated emissions. The below image illustrates the breakout of the most common types of equipment used in each category of testing. It's worth noting that some tests will have the same or similar types of test equipment, typically with changes in frequency or power. With enough considerations in the forefront, equipment can be purchased to meet several tests.

Some of the associated tests and related equipment will require substantial investments, such as radiated immunity testing with semi-anechoic chambers, while others can be done in a more common laboratory setting. As part of the product development cycle, this type of testing is often done a periodic basis to ensure the end result is able to meet the requirements without delays or costly revisions to the product's design

Compliant & Pre-compliance Testing

Pre-compliance testing will change or remove certain test criteria in order to get results "close" to the fully compliant test. In contrast, fully compliant testing will ensure every detail of the testing will be done according to standard. Pre-compliance testing is often done for testing revisions to a product or prior to sending equipment in to a test lab for certification.

When looking at pre-compliance equipment and test setups, they can range from almost compliant (except for one part or section of the standard) or almost completely modified. This creates a situation where pre-compliance testing can cover a wide range of testing and can vary substantially.

The choice of evaluating Pre-compliance testing comes down to:

- Availability or cost of purchasing the equipment or setup

- Capital required to conduct testing at a certified test lab

- Believed impact the equipment or setup has on the test results

ESD Simulators/Guns

Electrostatic discharge (ESD) simulators are devices used to test immunity to a quick release in energy caused by a difference in charge between two objects or people. This is one of the most common tests and is included in many commercial, military and automotive requirements. It is also tested at both the system level and component level. The most common of the basic system level requirements for commercial products is IEC 61000-4-2, which is often referenced by product specific requirements.

ESD simulators are typically broken down into a few major components, the display used for changing testing criteria, the trigger for applying the discharges, the high-voltage generator, and the discharge tip. This type of equipment is often used for pre-compliance and troubleshooting testing as the underlying requirements often cause failures and the equipment is relatively low cost.

Testing & Discharge Methods

Testing requirements will specify the test levels, resistance and capacitance of the simulator, preference on discharge method, and other criteria. The different discharge methods, air and contact discharge, are done using specially designed tips. These tips attach to the front of the simulator and apply the discharge to the equipment under test. Contact discharge is the generally the preferred method and air discharge is often used when contact discharge cannot be applied. As the name implies contact discharges maintains physical contact with the equipment while the discharges are applied. The air discharge tip is rounded and will release a discharge when the air gap is breached.

The discharge repetition and polarity will vary depending on the requirements of the underlying test standard, however are typically applied at a rate of less than 1 discharge per second and 10 discharges at each polarity.

Test Setup

commercial products are based on IEC 61000-4-2 which provides two different setups for table top and floor standing equipment. The diagram on the right from the user manual of the Teseq NSG 435 provides an overview of the table top setup.

Common components of an ESD Table top Setup Include:

- Horizontal Coupling Plane (HCP)

- Insulation placed under EUT

- All wood table

- Bleed off Cabling including resistors

- Ground Reference Plane

LISNs

Line impedance stabilization networks (LISNs) are measurement devices that are typically used in conducted emissions to monitor RF signal levels over a set frequency range while providing a stable impedance value. This test can be done either with a full compliant EMI receiver, or often for pre-compliance with a spectrum analyzer. Unlike some other EMC tests, this test can be accomplished with a relatively good degree of certainty at the pre-compliance level.

Typically LISNs are categorized by several factors including inductance, voltage and power limitations, frequency range, insertion loss, as well as compliance to specific requirements (often CISPR 16-1-2 & ANSI C63.4 for commercial applications). As a starting point, it's common to first determine the inductance of the LISN that's needed The different inductance values are used to replicate the inductance of the power system to which the equipment will be connected. For large systems and commercial (including large aircraft) requirements, 50 micro-Henry is often used whereas, for smaller systems (notably automotive) 5 micro-Henry is common. Typically the associated documentation will confirm compliance to a particular standard otherwise it can be confirmed with the manufacturer.

The analyzer should typically not be connected to the LISN until after the equipment has been powered up even if an attenuator or transient limiter is used. Transients can be caused potentially damaging the measuring instrument.

The associated image illustrates a pre-compliance setup designed for FCC Part 15 subpart B for unintentional radiators. In this setup we have our power input connected to the back of the LISN then our EUT connected to the front. Next from our LISN we have our spectrum analyzer connected to the type N connector measurement port. If the LISN doesn't have a built-in transient limiter/attenuator an external unit is typically placed between the spectrum analyzer/EMI receiver and the LISN.

LISNs with Spectrum Analyzer & EMI Receivers

While EMI receivers are typically used for compliant measurement to most requirements, spectrum analyzers are a great low-cost pre-compliance tool. Spectrum analyzers have a limited number of data points, typically at or around 200 or 300 depending on the make and model of the analyzer. Using some quick math given the bandwidth requirements of the standard, it can be determined how many sweeps are necessary given the limitations of the analyzer. For additional information on how this is calculated, TekBox has created an excellent application note that can be found by clicking here.

For conducted emissions measurements, it's possible radiated interference can couple onto lines causing interference not related to the EUT. In most test laboratory settings these measurements are conducted in a shielded environment that limits outside noise that could couple onto lines. When conducting pre-compliance testing it's ideal (if possible) to select an area away from other equipment including printers, computers, etc.

The scan(s) are compared in relation to limits in the underlying requirement and are illustrated with a limit line that extends across the related frequency ranges. If a spectrum analyzer is used the multiple scans are then combined together to provide a complete sweep over the frequency range of interest. With EMI receivers these scans can be completed in a single sweep saving time.

Conducted Emissions

Conducted emissions measurements are typically done using Quasi-peak, peak, and average detection methods as specified by CISPR 16-1. For many commercial requirements, measurements are typically in dBuV as with FCC Part 15 mentioned earlier. Quasi-peak, as opposed to a peak measurement, weighs the signal depending on the repetition rate of the signal.

Often scans are run in peak detection first, given they are less time intensive, and if areas of concern are found, they are run again in quasi-peak and compared to the limit.

The image below from the EDN.com article "EMI Emissions testing: peak, quasi-peak, and average measurements" illustrates how quasi-peak, peak, and average measurements are made. As mentioned above the quasi-peak detector reading will be higher when the frequency of the event increases.

Transient Generators

Transient generators are designed to create both impulse and oscillatory transient waveforms to test the immunity of equipment to these impulses. These immunity test systems are typically used in conjunction with a coupling decoupling network (CDN) allowing for injection of the waveform on power or data lines. In most situations a single-phase CDN is built-in the test system with external CDNs required for testing high voltage, three-phase, or data lines.

Most commonly transient generators can be configured to meet specific requirements commonly defined by IEC/ANSI requirements.

- This common testing capabilities for transient generators:

- Combination Wave Surges - IEC 61000-4-5

- Electrical Fast Transients - IEC 61000-4-4

- Ringwave - IEC 61000-4-12

- Telecom Surges - IEC 61000-4-5

- Voltage Dips - IEC 61000-4-11

Coupling Decoupling Networks

When conducting transient immunity testing, the interference is typically applied to the cables of the EUT and subsequently to the associated ports. For most tests this is applied using a CDN, the exception being EFT/Burst testing on data lines where a capacitive coupling clamp is used. Specialized CDNs are used for high voltage, high current, three-phase, or data lines. For compliant testing of power lines, CDNs will require communication (ensuring line synchronization) with the transient generator and will need to be from the same manufacturer.

The below image shows a few different coupling devices and the associated type of cable and test it is designed for.

Power on Testing

Any power-on testing (where EUT is turned on) must be done through the CDN or damage to the associated equipment will occur.

Applying the transients while the equipment under test is powered on is the most common method used to conduct testing. For most test systems the power for the equipment is fed to the back of the CDN and the equipment is connected to the front. Depending on the power requirements of the EUT an external programmable source can be used.

Once the EUT has been connected and powered on the different test criteria can be selected from the front panel display or software. Most test systems on the market today have preprogrammed standards allowing for the entire test routine to be run according to the test parameters.

RF & Microwave Amplifiers

Radiofrequency and microwave amplifiers are used in both radiated and conducted immunity testing to expose equipment to a modulated sine wave to replicate interference threats. These devices are used in conjunction with a signal generator to provide enough power to drive the radiating element or injection device to meet the required levels.

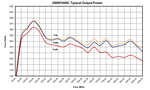

Amplifiers used in EMC are typically categorized by several factors including frequency range, power, VSWR tolerance, and modulation formats. The power is typically provided in both Psat where the output power is saturated and P1dB is the amplifier at the 1dB compression point. When determining the power that is needed, often working backward from the antenna is a preferred method to determine the power needed to achieve an associated field level.

The associated image from the Amplifier Research 250W1000C solid state broadband class A power amplifier designed for operation from 80 MHz to 1000 MHz shows both the Psat and P1dB extending slightly above and below the frequency range.

Classes of Amplifiers

Amplifiers used for immunity testing in EMC are generally designed in three different classes each offering different characteristics.

Class A Amplifiers: Designed to operate with active devices in a full 360 degree conduction angle. Provides the most linear performance and is less sensitive to mismatch loads (reverse power) making it ideal for EMC applications, however it is the least efficient.

Class AB Amplifiers: Combines elements of Class A and B amplifiers to get the advantages of both. This class of amplifiers is capable of linearity approaching that of class A but with higher efficiency, however the lower mismatch tolerance can prevent them from being used with common EMC transducers.

Class B Amplifiers: Provides a 180-degree conduction angle to save energy and increase efficiency. Typically Class B amplifiers are far more efficient than Class A amplifiers at around 70%. Class A tend to be less than 50% efficient.

Solid-state & TWT Amplifiers

There are two major designs of amplifiers commonly in use for EMC testing. Solid -state amplifiers (SSPAs) and traveling-wave tube amplifiers (TWTAs). Solid-state amplifiers typically use transistors while traveling-wave tube use a vacuum tube. Each type offers benefits, however a major disadvantage of the TWTs is the delicate nature of the tubes. These tubes make up a large portion of the costs and damage to the tubes is either extremely costly to repair or unrepairable. As solid-state amplifier development continues it's become common to see them at higher frequencies, with TWTs used for specialty high-power applications, commonly for military or aerospace applications.

Antennas

Antennas are commonly used for both receiving for radiated emissions and propagating fields for immunity testing. Certain characteristics of antennas make them more beneficial for EMC testing depending on the application including operating frequency, antenna factor, antenna gain, power handling, polarity, and VSWR. Antennas are commonly used for compliant, pre-compliant, and on-site/in-situ testing and are often designed in accordance with the underlying standard or requirement (if guidance is present).

While there is a large variety of antennas available, typically for most commercial applications certain antennas tend to be used for certain frequencies.

Biconical Antenna - These two-element broadband antennas are typically used from ~25 MHz to up to 200/300 MHz.

Log-Periodic Antenna - Typically used from ~300 MHz to 1 GHz with smaller elements receiving for higher frequencies and larger elements for lower frequencies.

Horn Antenna - Typically used at frequency ranges greater than 700 MHz, it's common to see the double-ridge guide antennas.

Specialty Antennas

These antennas are focused on specific characteristics or requirements, particularly those at low or high frequencies, or high power. well. The more specialized antennas will often have higher power handling, extended frequency ranges, combine elements of multiple antennas, or have the design designated by the test standard. This is common in military, automotive and pre-compliance applications.

Below are some of the most common:

- BiConiLog Antennas - A combination of a log-periodic and other elements which extend the useable frequency in a single antenna. Typically covering from ~30 MHz to ~3/6 GHz.

- Active-Loop Antennas - Used for radiated emissions testing from 9 kHz to 30 MHz, commonly used commercial requirements.

- E-Field Generating Antennas - Antennas used for generating high strength RF electric fields typically for military from 10 kHz ~100 MHz with high power handling.

- Pre-compliance Receiving Antennas - A variety of low cost antennas are on the market for pre-compliance radiated emissions.

- High Gain Horn Antennas - High-power horn antennas commonly used in automotive testing from 200 MHz ~ 6 GHz provide improved directivity and broad bandwidth.

Monitoring Devices

There are a variety of verification devices used in EMC testing both for immunity and emissions. These devices are typically ISO 17025 calibrated annually to ensure the proper operation. Each test or application will typically have some kind of verification procedures to ensure that the equipment is functioning properly and the associated test levels are met. This can take the form of a field probe used to measure radiated fields or a monitoring probe used to verify waveforms of a transient generator.

E-Field Probes

Electric field probes are the devices used to measure radiated immunity field strengths at a prescribed distance across the uniform field area (where the equipment will be placed). A continuous wave without modulation for is typically used for commercial applications. These probes will typically be limited by frequency range, field strength, and modulation monitoring capabilities. These probes are integrated with a radiated immunity systems to make the necessary adjustments to meet the desired test levels.

The system includes a probe and an interface component which will allow for connections to multiple probes and to the control software.

Current Monitoring Probes

Current monitoring probes are used for multiple applications including conducted emissions, RF immunity testing, and transient waveform verification. These devices produce voltage (into a 50 Ohm load) in proportion to current moving through the probe aperture/window. The cables are placed through the probe aperture and there is no direct contact to the conductors in the associated cabling. They are commonly made of a ferrite type material and are available in clamp/snap on versions allowing for easy placement around cabling.

These verification devices provide different frequency ranges, power handling capabilities, sensitivity, and internal diameters. Certain applications such as waveform rise time measurements, require specific characteristics often requiring specific probes for certain applications. The probe shown on the right, the Fisher F-33-2 is often used for both conducted emissions and immunity testing. For additional information on current monitoring probes, A.H. Systems has created an excellent article on Understanding and Implementing RF Current Probes.

EMC Test Equipment & Applications FAQ

The purpose of EMC is to determine if equipment is designed robustly enough to operate in its intended electrical environment and to ensure it doesn't create interference that would impact other equipment in that environment.

EMC requirements are test standards used to evaluate equipment under test (EUT) compliance. They are split between generic, product, and basic standards, with basic standards providing the testing guidance and information on testing phenomena.

References:

- Amplifier FAQs. (2019). Ametek-Cts.com. https://www.ar.ametek-cts.com/knowledge-center/faqs/amplifier-faqs

- Browne, J. (2015, April 14). What’s the Difference Between TWTAs and SSPAs? Mwrf.com; Microwaves & RF. https://www.mwrf.com/technologies/article/21846179/whats-the-difference-between-twtas-and-sspas

- EDN. (2018, July 10). EMI emissions testing: peak, quasi-peak, and average measurements - EDN. EDN. https://www.edn.com/emi-emissions-testing-peak-quasi-peak-and-average-measurements/

- Go to School on RF Power Amplifier Classes - Mini-Circuits Blog. (2021, March 26). Blog.minicircuits.com. https://blog.minicircuits.com/go-to-school-on-amplifier-classes/

- Samuels, T. (2023). Understanding and Implementing RF Current Probes. Ahsystems.com. https://www.ahsystems.com/articles/Understanding%20and%20Implementing%20RF%20Current%20Probes.php

- What Is Quasi-peak Detection? - Technical Support Knowledge Center Open. (2024). Keysight.com. https://docs.keysight.com/kkbopen/what-is-quasi-peak-detection-588264161.html

- What is Quasi Peak – Atlas Compliance & Engineering. (2020). Atlasce.com. https://atlasce.com/services/emissions-testing/what-is-quasi-peak/

- What is the meaning of P1dB and Psat as stated in amplifier specifications? - Technical Support Knowledge Center Open. (2024). Keysight.com. https://docs.keysight.com/kkbopen/what-is-the-meaning-of-p1db-and-psat-as-stated-in-amplifier-specifications-588278275.html

- What is a TWT Amplifier? - everything RF. (2020, October 12). Everythingrf.com. https://www.everythingrf.com/community/what-is-a-twt-amplifier